KPS INDUSTRIES INC. has a 6-acre fabrication facility and assembly yard located in Central Alberta just off Highway QEII.

We are capable of executing the assembly of various module package sizes, while focusing on cost control, scheduling, safety and quality. We have multiple Over Head Cranes of 2-10 Tons and 2-30 Tons.

Our module assembly shop & yard incorporates up to date equipment and procedures to achieve the highest level of quality the industry demands.

We provide custom engineered, Canadian-made, heat transfer technology packages for a variety of applications and industries. We will provide complete Mechanical Assembly, Building, Instrumentation and Electrical Installations, and assist with Site Start-Up/Commissioning and Maintenance as requested.

Heater Field Services division:

For all Heaters, Burners, BMS and Fuel Gas System Upgrades, Maintenance, Start-Up and Commissioning throughout

Western Canada.

Based in Fort St. Johns B.C., our experienced technicians hold

Class A Gas Fitters qualifications

TSBC Class A BOILERS license LBP0212025

Our products include:

- Process Heat Medium (Boiler) Packages

- Line Bath Heater Packages

- Air Coolers (fin tube-fan) Heaters

- WHRU (Waste Heat Recovery) Ducts

- Reboilers, Amine Reboilers

- Direct Heaters

- Indirect Heaters

- Helical Coils

- Shell & Tube Heat Exchangers

- API 560 Fired Heaters (Furnaces)

- Process and Thermal Fluid Heaters

- Replacement Bundles, Furnace Coils and Components

- Re-tubing, cleaning and testing Exchangers & Air Coolers

- Repairs, alterations & modifications to Heat Exchangers

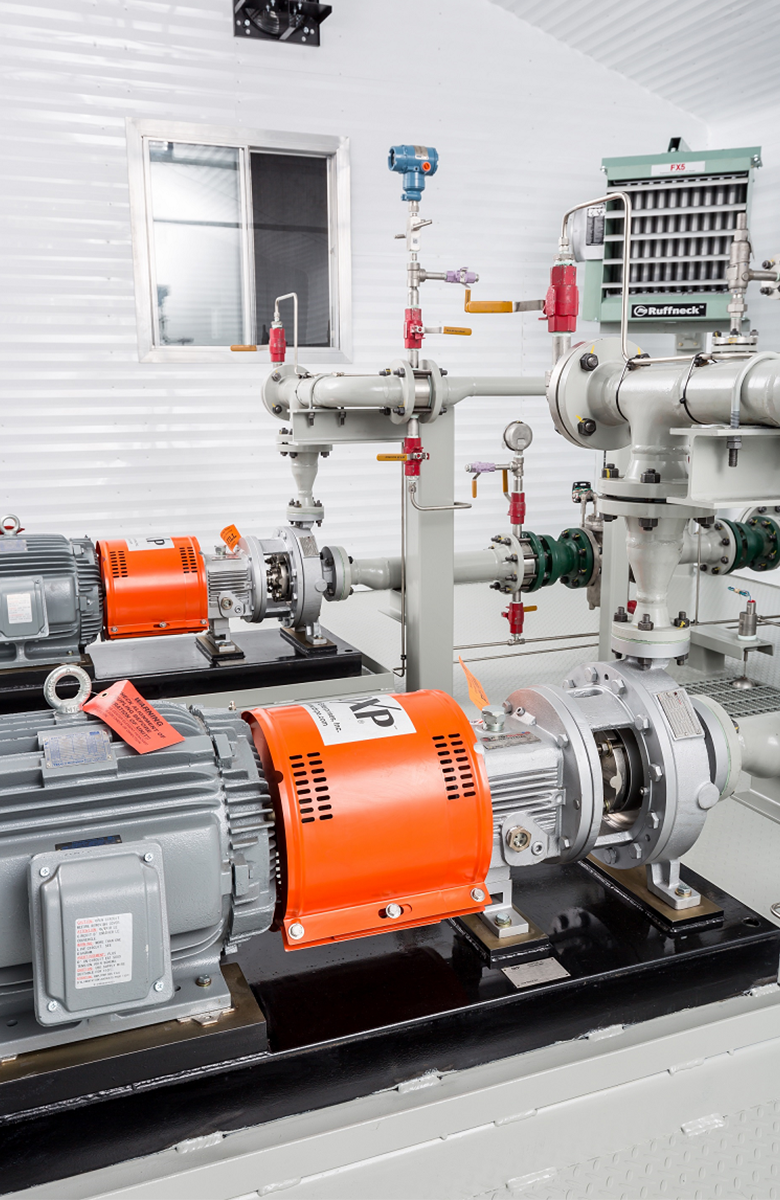

KPS Industries Inc. provides competitive pumping systems solutions with dedicated delivery and pricing. All pump configurations, unitized pump assemblies and design builds of turnkey pump packages can be accommodated.

We can also provide custom designs meeting our clients’ specifications and requirements.

- Vapour Recovery Units

- Multiphase Pump Packages and Pumps

- Pumps, Pump Unitizations & Complete Packages

- Pumps sizing and selection with Distributor level pricing

- Condensate Pump Packages

- Water Injection Pump Packages

- Skim/Recycle Pump Packages

- Metering Units

- Dehy Packages

- Inlet and Group Separator Packages

- Water Treatment Packages

- Oil Treating and Upgrading

- Satellite (Multi-Well) Packages

- Flare Knock Out Drums / Packages / FWKO

- Custom Designed Skids

- Genset Generator Equipment Skid Packages

KPS INDUSTRIES INC. provides Fabrication for all of your Piping Spools, Pressure Vessels and Structural requirements. KPS facilities can accommodate quality product development from start to finish. Our location allows us to offer onsite fabrication, sandblasting, NDT (non-destructive testing), hydro testing and painting.

- B31.3/B31.1/CSAZ662 Piping Fabrication – give us your ISOs and We will SpoolFab, Fit & Weld, RT & MT and Hydrotest!

- 12,000 Factored Diameter Inches per month

- Pipe spools from 2” to 48” NPS with Carbon, stainless & alloy

- WPS registered to ASME in the As Welded or PWHT Condition

- Pipe spools & headers, Pig launchers & receivers, Jacketed Piping

- Coating and Internal Coating of piping systems

- Mainline Valve Assemblies fabrication

- ASME Vessel design and registrations of all custom vessel designs

- ASME SECTION I, IV, VIII Div.1 Heaters and Vessels Fabrication

- ASME U & S Code Stamps available

- National Board Certificate of Authorization

- Vertical & Horizontal Separators, Suction & Discharge Bottles

- Exchanger vessels, Filter vessels, Knockouts and Blow Cases

- All Structural steel solutions CSA W47.1 CWB Division 2

- Weekly client progress reporting